Introduction

In modern construction, quality, consistency, and efficiency are paramount. Ready-Mix Concrete (RMC) has become an essential material for building durable and reliable structures, offering significant advantages over traditional on-site mixing.

CDC Ready-Mix Concrete is dedicated to supplying high-quality concrete solutions that meet the demands of contemporary construction projects. Our range includes conventional concrete, high-strength concrete, high-performance concrete, self-compacting concrete, and lean mixes, ensuring the right solution for every structural requirement.

Importance of RMC in Modern Construction:

Quality and Consistency: Automated batching ensures uniform mix quality for every batch, reducing construction defects.

Time Efficiency: RMC is delivered ready-to-use, saving on-site mixing time and accelerating project timelines.

Cost Efficiency: Reduced labor and material wastage lower overall construction costs.

Structural Strength: Precisely controlled mix designs achieve the desired strength, enhancing safety and durability.

Sustainability: Optimized mix designs and precise dosing minimize material wastage and reduce environmental impact.

WHY USE READY MIX CONCRETЕ??

- Better Quality can be achieved

- RMC saves a lot of time

- W/C ratio can be maintained accurately

- Very ease in construction

- Higher strength can be achieved

- Less quantity of labor is required

- No uncertainty for achieving strength

- Various strength can be obtained

- Helps to finish construction as per schedule time

- Save site space for materials stacking

- Eco friendly due to less wastage of material

CDC READY MIX CONCRETE RESOURCES

At CDC Ready-Mix Concrete & Block, we believe that the strength of concrete defines the strength of your structure. The required degree of strength varies with the scale and type of construction — and achieving it depends entirely on the quality and consistency of the concrete used.

CDC Ready-Mix Concrete ensures that every batch meets the desired and specified strength, maintaining superior quality and durability for every project.

Our production is fully software-controlled and operated by automated PLC systems, ensuring precision in every mix. We operate two batching plants, each with a production capacity of 60 m³/hour, delivering a total capacity of 120 m³/hour.

Our advanced logistics and support facilities include:

- 05 high-performance concrete pumps for efficient on-site delivery.

- 24-hour continuous production supported by 02 diesel generators.

- 20 brand-new transit mixer trucks (each with 8 m³ capacity).

- 04 cement silos with a combined capacity of 400 metric tons.

- A fully equipped concrete research and testing laboratory.

- 02 deep tube wells ensuring a continuous supply of fresh water.

- 05 pickup trucks for carrying concrete pumps and pipelines.

- 01 covered van dedicated to laboratory operations.

- An in-house digital diesel filling station with 15,000 liters storage.

- An own weighbridge scale for accurate measurement and quality assurance.

CDC READY MIX RAW MATERIALS

Cement (OPC/ PCC)

"Cement brands such as Seven Rings Cement, Lafarge Holcim, and Scan are used exclusively in the production of CDC Ready-Mix Concrete."

Fine Aggregate (Sand)

Clean "Sylhet Sand" directly sourced from Sylhet which can be found in convenient sizes for mixing purposes with FM greater than 2.5.

Coarse Aggregate (Stones)

"Dubai LC, Dubai Gabro, and Lafarge Holcim aggregates from Meghalaya are used exclusively in CDC Ready-Mix Concrete."

Water

Fresh potable water from a deep tube well established in each plant is used in CDC Ready-Mix Concrete.

Chemical Admixture

"For superplasticizing and retarding purposes, imported admixtures from Germany, UAE and India, such as Sika, Conmix, BASF, and SBT, are used in CDC Ready-Mix Concrete."

QUALITY CONTROL

CDC Ready-Mixed Concrete is supplied in a wide range of grades and compositions to meet the unique demands of every project — from simple residential homes to high-performance concrete for complex mega projects. Our solutions are tailored to deliver strength, durability, and reliability, exactly where it is needed.

Each of our plants features state-of-the-art laboratories, equipped with the latest testing machines to carry out both routine and advanced tests on raw materials and freshly produced concrete. These laboratories operate in full compliance with international standards, including ASTM, ACI, AASHTO, BS, IS, and the Bangladesh National Building Code (BNBC), ensuring every batch meets the highest quality benchmarks.

At CDC, quality assurance is not just a step — it’s a process embedded in every stage of our operations. From order processing, material procurement and control, and concrete mix design to production, delivery, and on-site monitoring, we ensure that every cubic meter of concrete meets the design and performance requirements of your project.

LAB FACILITY

Fully equipped laboratories have been set up at our plants to carry out various tests on concrete and on constituent raw materials. Concrete mixes of various grades are designed in a laboratory as per established procedures to comply with Standard Specification. The following tests are performed in our laboratory arrangement:

- Fineness Modulus (FM)

- Moisture Content & Water Absorption

- Unit Weight

- Specific Gravity

- Silt & Clay Content

- Gradation

- Aggregate Crushing Value (ACV)

- Los Angles Abrasion Test

- Flakiness & Elongation

- Compressive Strength Fineness

- Consistency

- Setting Time

- Slump Test

- Admixture Test

BUET TEST

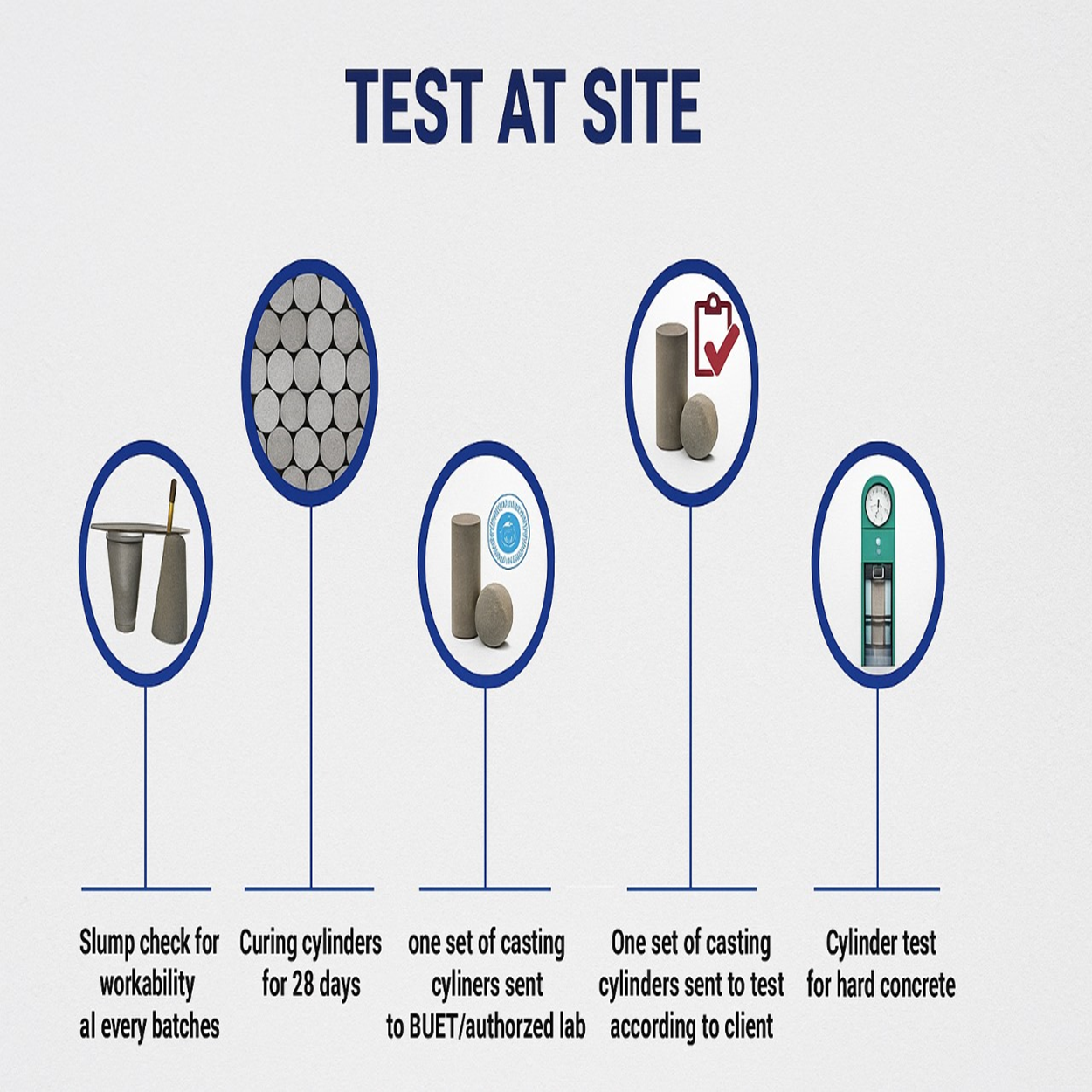

The concrete is cured in the curing tank for 28 days and then a set is sent to BUET lab for getting the supplied concrete strength. The test result is very important for the acceptance of on-site concrete work since it demonstrates the strength of the mix design.